AIR HANDLING SYSTEM

FAN COIL UNITS

Unique and simple design with high quality installation part in good way with different speed.

SLIM AND COMPACT DESIGN

Light and rigid construction due to compact and strong design of the unit. Slim unit design also fulfills the stringent space requirement of today’s building design.

SIMPLE INSTALLATION

Unique design of fan coil units allow easy on-site modifications of water pipes configuration (left or right). Accessories are also available to ensure trouble-free installation.

EASY MAINTENANCE

The fan coil units are equipped with high quality electrical motor with low noise bearing that do not require lubrication and thus minimum maintenance effort required. Blowers and also motors can be dismantled individually if cleaning of heat exchanger is needed.

HIGH EFFICIENCY HEAT EXCHANGER

High quality copper pipes with slit profile aluminum fins are being transformed into high efficiency heat exchanger through advance design, manufacturing equipment and processes.

NO LEAKAGE

One piece molded drain pan with integral thermal insulation and professional welding skill enable all condensate water to be collected and prevent condensation at the outside of the drain pan.

SUPERIOR PRODUCT QUALITY

All fan coil units are manufactured in ISO9001:2015 certified manufacturing facility whereby highest products’ quality is always top priority. The products’ high quality standard has been recognized through successfully obtaining the CE marking certification which in turn comply with the stringent EU requirements.

1.1. CEILING CONCEALED FCU

Standard fan coil units come with 3 rows coil which provide high ESP (30Pa and 60Pa) options to suit different application.

RANGE

| Model | FCR300 ~ 1400E |

| Airflow | 280 ~ 2,400 CMH 165 ~ 1,412 CFM |

| Total Cooling Capacity | 2.29 ~ 13.00 kW |

| Power Supply | 220 ~ 240V / 1Ph /50 ~ 60Hz |

1.2. LOW NOISE CEILING CONCEALED FCU

Provide superb low noise performance with high quality electrical motor and supply cool air and smoothly, making your environment comfortable.

RANGE

| Model | FCRQ400 ~ 800B |

| Airflow | 340 ~ 1,360 CMH 200 ~ 800 CFM |

| Total Cooling Capacity | 2.93 ~ 7.95 kW |

| Power Supply | 220 ~ 240V / 1Ph / 50 ~ 60Hz |

1.3. HIGH DELTA-T CEILING CONCEALED FCU

Suitable non-standard options with high chilled water different temperature and ESP (75 Pa).

RANGE

| Model | FCR300 ~ 1400B |

| Airflow | 330 ~ 2,750 CMH 194 ~ 1,618 CFM |

| Total Cooling Capacity | 1.78 ~ 13.73 kW |

| Power Supply | 220 ~ 240V / 1Ph / 50 ~ 60Hz |

1.4. HIGH AIR VOLUME FCU

Provide a smoothly air directly to where you need and units suitable for high external static pressure (ESP) which is 130 Pa and also with height of only 430mm is most suitable for applications that demand for high air flow but with space saving in mind.

RANGE

| Model | FFM800 ~ 3,000BH |

| Airflow | 815 ~ 5,500 CMH 479 ~ 3,235 CFM |

| Total Cooling Capacity | 5.30 ~ 34.41 kW |

| Power Supply | 220 ~ 240V / 1Ph / 50 ~ 60Hz |

1.5. CEILING CASSETTE FCU

Provides cool and comfort air with four different air direction equipped with high motor efficiency with low noise by pointing to each side.

RANGE

| Model | FKM500 ~ 1400A |

| Airflow | 425 ~ 2,380 CMH 250 ~ 1,400 CFM |

| Total Cooling Capacity | 2.90 ~ 12.60 kW |

| Power Supply | 220 ~ 240V / 1Ph / 50 ~ 60Hz |

1.6. WALL MOUNTED FCU

It can install easily due to its light weight and slim body. It also provide different speed that will satisfy the desired airflow with minimum noise levels.

RANGE

| Model | FWM300 ~ 800A |

| Airflow | 255 ~ 1,360 CMH 150 ~ 800 CFM |

| Total Cooling Capacity | 1.70 ~ 7.20 kW |

| Power Supply | 220 ~ 240V / 1Ph / 50 ~ 60Hz |

AIR HANDLING UNIT

SPECIAL PANEL STRUCTURE DESIGN

FFD’s and FAD’s panel is made of powder coated steel (outer) and galvanized steel (inner) with high pressure PU foam sandwiched in between, thus producing a rigid and robust panel 25mm for FFD and FAD and also available upon request for panel 50mm (FBD). Units come with strong and lightweight panel structure designed which reinforced with specially designed hidden aluminum alloy frame that are being fastened to the panels with bolts and nuts.

LOW AIR LEAKAGE

Patented “Labyrinth” panel design featuring integrated frame and panel structure, proprietary aluminum profile fastened with bolts and nuts and ingeniously designed insulation method, reduces the connecting edges which produces a leading edge low air leakage panel structure.

LOW NOISE

Rigidly bolted panels, dynamically and statically balanced fan assembly with spring isolator and closely integrated sections reduces the vibrations and noise generated, thus providing a quiet operation air handling unit.

NO COLD BRIDGE

High pressure foam sandwiched between panels and specially designed insulation method is isolating all metal surfaces inside the air handling unit from outside air which eliminate the possibility of cold bridge. Thus, no condensation will happen and at the same time minimize loss of energy.

COMPUTER AIDED COIL DESIGN

All cooling is designed using professional computer selection software which is carefully formulated. Designed and being fine-tuned through laboratory testing and real life application.

2.1. 3 SPEEDS DIRECT DRIVEN CEILING MOUNTED

RANGE

| Model | FSAD010 – 070ECC |

| Airflow | 525 ~ 6,300 CMH 309 ~ 3,706 CFM |

| Total Cooling Capacity | 3.30 ~ 88.40 kW |

| Power Supply | 220 ~ 240V / 1Ph / 50 ~ 60Hz |

2.2. BELT DRIVEN, CEILING MOUNTED

RANGE

| Model | FSAB040 – 150ECD |

| Airflow | 3,570 ~ 14,175 CMH 2,100 ~ 8,338 CFM |

| Total Cooling Capacity | 19.80 ~ 216.30 kW |

| Power Supply | 380 ~ 415V / 3Ph / 50 ~ 60Hz |

2.3. BELT DRIVEN, HORIZONTAL & VERTICAL

RANGE

| Model | FSAH/FSBH030 – 500DH/DV |

| Airflow | 2,831 ~ 47,691 CMH 1,665 ~ 28,054 CFM |

| Total Cooling Capacity | 14.90 ~ 685.90 kW |

| Power Supply | 380 ~ 415V / 3Ph / 50 ~ 60Hz |

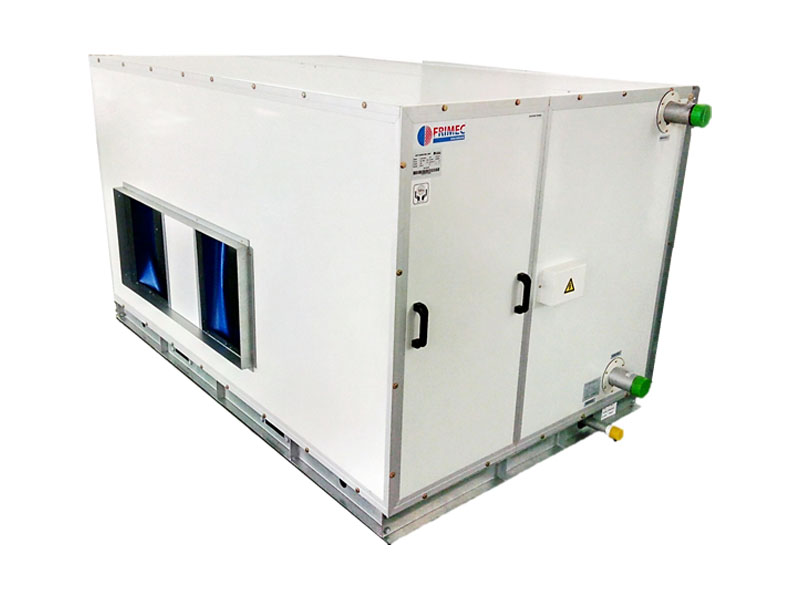

MODULAR AIR HANDLING UNITS

FRIMEC provide best design in flexibility and robust to suite different site conditions. Units easy to install packages and high energy efficiency which produce a good quality air, making your environment comfortable while reducing maintenance requirements. Indoor and outdoor units are available to handle a wide variety of applications.

MODULAR DESIGN

FAC/FBC’s design is adopting modular concept in both length and width which it make flexible and robust for installation in different site conditions. Panels are fastened with bolts and nuts, thus making site installation work easy but with factory standard assembly finishing.

SPECIAL PANEL STRUCTURE DESIGN

AHU’s panel is made of powder coated steel (outer) and galvanized steel (inner) with high pressure PU foam sandwiched in between, thus producing a rigid and robust panel 25mm and 50mm. Units come with strong and lightweight panel structure designed which reinforced with specially designed hidden aluminum alloy frame that are being fastened to the panels with bolts and nuts.

LOW AIR LEAKAGE

Patented “Labyrinth” panel design featuring integrated frame and panel structure, proprietary aluminum profile fastened with bolts and nuts and ingeniously designed insulation method, reduces the connecting edges which produces a leading edge low air leakage panel structure.

LOW NOISE

Rigidly bolted panels, dynamically and statically balanced fan assembly with spring isolator and closely integrated sections reduces the vibrations and noise generated, thus providing a quiet operation air handling unit.

NO COLD BRIDGE

High pressure foam sandwiched between panels and specially designed insulation method is isolating all metal surfaces inside the air handling unit from outside air which eliminate the possibility of cold bridge. Thus, no condensation will happen and at the same time minimize loss of energy.

COMPUTER AIDED COIL DESIGN

All cooling is designed using professional computer selection software which is carefully formulated. Designed and being fine-tuned through laboratory testing and real life application.

BUILT IN LEVELER

Base frame is equipped with built in leveler to ease the leaving work between sections. This will ensure seamless integration of modules which is turn eliminate air leakage, vibration and providing an unsurpassed finishing.

RANGE

| Model | FAC (25mm) / FBC (50mm) |

| Airflow | < 3,000 (25mm) / 30,000 ~ 300,000 (50mm) CMH |

| Total Cooling Capacity | <1,000 Pa / 1,000 < TSP < 2,000 Pa |

CHILLERS

AIR-COOLED MINI CHILLER

Product with slim and compact design minimise the space needed for installation. It can be integrated easily with any architectural design either residential or light commercial area.

BUILT IN PUMP & EXPANSION TANK

Maximum pump head up to 13m and expansion tank provided to protect closed water systems

CONTROL

Wired LCD controller equipped with various operating mode, timer setting, and self-diagnosis in error code.

QUIET & EFFICIENT COMPRESSOR

Japanese leading brand scroll compressors that have been proven with superior performance and quiet operation.

RANGE

| Model | FALC050 ~ FALC100 |

| Total Cooling Capacity | 14.5 kW ~ 29.0 kW 4 TR ~ 8 TR |

| Refrigerant Type | R410A |

| Power Supply | 380 ~ 415V / 3Ph / 50Hz |

AIR-COOLED MODULAR CHILLER

Small and compact chiller that allows flexible expansion that will fit your space without neglecting the cooling performance that you desired.

SIMPLE INSTALLATION

No cooling tower required.

SAFETY PROTECTION

Built in protections for all subsystem, i.e. refrigerant system, electrical system and water system.

FLEXIBILITY AND ENERGY SAVING

Modular system up to 8 modules is able to adhere to different load profile precisely and delivery highest performances at all load condition.

RANGE

| Model | FAMC 201 ~ 601 |

| Total Cooling Capacity | 66 kW ~ 1624 kW 18.8 TR ~ 462 TR |

| Refrigerant Type | R410A |

| Power Supply | 380 ~ 415V / 3Ph / 50Hz |

WATER-COOLED MODULAR CHILLER

Small and compact chiller provide great flexibility of matching the exact load demand of applications yet energy saving and high efficiency

EASY MAINTENANCE

Wired LCD controller equipped with various operating mode, timer setting, temperatures display and self-diagnosis by error code.

SAFETY PROTECTION

Built in protections for all subsystem, i.e. refrigerant system, electrical system and water system.

FLEXIBILITY AND ENERGY SAVING

Modular system up to 8 modules is able to adhere to different load profile precisely and delivery highest performances at all load condition.

RANGE

| Model | FWMC 20 ~ 70 |

| Total Cooling Capacity | 70 kW ~ 1960 kW 20 TR ~ 560 TR |

| Refrigerant Type | R410A |

| Power Supply | 380 ~ 415V / 3Ph / 50Hz |

AIR-COOLED SCREW CHILLER

Product with slim and compact design minimise the space needed for installation. It can be integrated easily with any architectural design either residential or light commercial area.

INTELLIGENT CONTROLS

The system is controlled through PLC and user is able to monitor and change the system setting through user-friendly touch screen panel. Connection for BMS port available.

RELIABLE

Using Europe leading brand high efficiency profile & compact screw compressor.

OZONE LAYER PROTECTION

Zero ozone depletion potential refrigerant, HCFC R134A.

RANGE

| Model | FASC100.1 ~ 345.2 |

| Total Cooling Capacity | 338 kW ~ 1216 kW 96 TR ~ 345 TR |

| Refrigerant Type | R134A |

| Power Supply | 380 ~ 415V / 3Ph / 50Hz |

WATER-COOLED FLOODED SCREW CHILLER

Product that are specially design for stability, high efficiency yet energy saving by utilizing precise control of system capacity versus load, great flexibility of cooling range and user-friendly system with intelligent remote-control monitoring.

RELIABLE

Using Europe leading brand high efficiency profile & compact screw compressor.

INTELLIGENT CONTROL

The system is controlled through PLC and user is able to monitor and change the system setting through user-friendly touch screen panel. Connection for BMS port available.

FLOODED TYPE EVAPORATOR

Flooded type evaporator provides higher heat transfer and better utilization of the surface area.

RANGE

| Model | FWSF 125.1 ~ 420.3 |

| Total Cooling Capacity | 435 kW ~ 1466 kW 124 TR ~ 418 TR |

| Refrigerant Type | R134A |

| Power Supply | 380 ~ 415V / 3Ph / 50Hz |

DIRECT EXPANSION SYSTEM

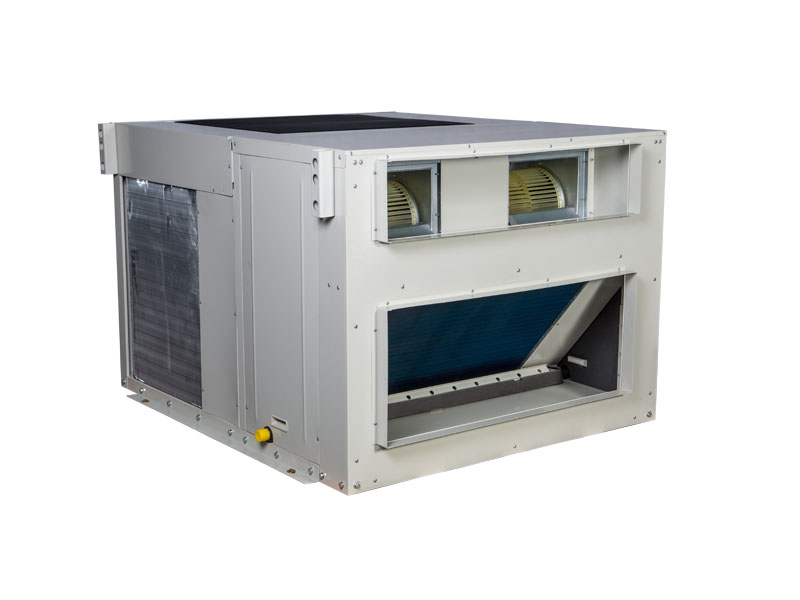

AIR-COOLED ROOFTOP PACKAGE

Compact and rigid single unit construction provides convenient installation with no additional piping work as both indoor and outdoor sides are pre-connected.

COMPACT DESIGN

The unit casing is made of external painted sheet metal suitable for outdoor application. The unit’s flat top design allows unit to be stacked up and provides maximum usage of warehouse and container space.

CONTROL

Mechanical system allows the unit to be operate as standalone system and allows to be connected to any BMS.

EASY FOR SERVICING

Unit can be serviced from external of the building without entering the premises.

RANGE

| Model | FACP8A ~ FACP32A |

| Total Cooling Capacity | 24 kW ~ 100 kW 8 Hp ~ 34 Hp |

| Refrigerant Type | R407C |

| Power Supply | 380 ~ 415V / 3Ph / 50 ~ 60Hz |

WATER-COOLED PACKAGE

MULTI-SYSTEM

Unit use multi-system design, featuring multiple individual refrigerant circuitry to enable capacity staging. Thus, part loading is possible during off-peak conditions which enable more energy saving.

EASY INSTALLATION

Direction of water connection pipe is changeable to suit site conditions, providing flexibility in installation.

MICROCOMPUTER CONTROLLED

Multiple modes supported. Controller is equipped with LCD display and supports Energy Saving, Alarm on system error, Self Diagnosis and able to display Set Temperature and Return Air Temperature.

RANGE

| Model | FWCP15 ~ FWCP100 |

| Total Cooling Capacity | 37.9 kW ~ 280.0 kW 15 Hp ~ 100 Hp |

| Refrigerant Type | R407C & R410A |

| Power Supply | 380 ~ 415V / 3Ph / 50Hz |

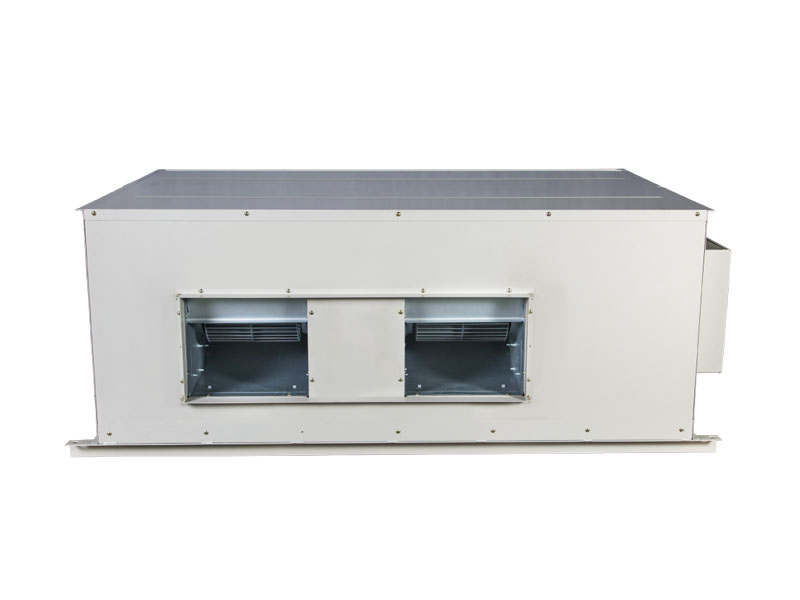

AIR-COOLED DUCTED SPLIT

FRIMEC air-cooled ducted split system has quality and reliability built-in. An indoor section and matching outdoor(s) section are connected by refrigerant tubing (hence the name “split”).

The indoor section consists of a fan, indoor cooling coil, and filter. The indoor units with larger capacity and airflow requirement are built with double skin panels made of powder coated steel (outer) and galvanized steel (inner) injected with high pressure PU foam.

The outdoor section houses the compressor and condenser. The outdoor units are using scroll compressors that have been proven to have superior performance and quiet operation.

RANGE

| Indoor Unit | FASN080 ~ FASN600 |

| Outdoor Unit | FASD080 ~ FASD150 |

| Total Cooling Capacity | 23 kW ~ 176 kW 8 Hp ~ 60 Hp |

| Refrigerant Type | R407C |

| Power Supply | 380 ~ 415V / 3Ph / 50Hz |

| Indoor Unit | FASN080 ~ FASN750 |

| Outdoor Unit | FASD080 ~ FASD150 |

| Total Cooling Capacity | 23 kW ~ 220 kW 8 Hp ~ 75 Hp |

| Refrigerant Type | R410A |

| Power Supply | 380 ~ 415V / 3Ph / 50Hz |

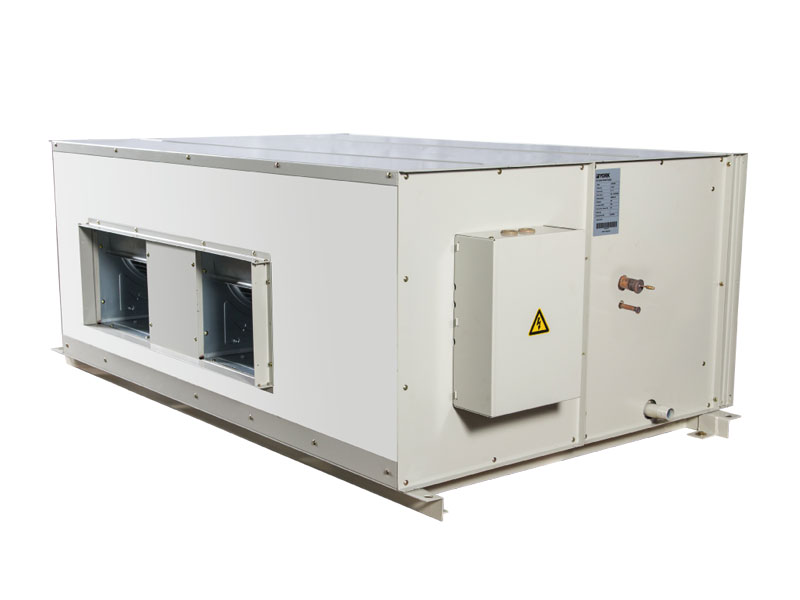

WATER-COOLED DUCTED

ENERGY SAVING & HIGH EFFICIENCY

Uses water as cooling medium which has higher efficiency compare to air. Simultaneous cooling can be achieved through water loop system, providing comfort and cost saving.

LOW NOISE

Without the need of air for cooling, unit can be installed in any place. Thus, air noise has been eliminated.

SIMPLE CONTROL

System is controlled by microcomputer which offers accurate and simple operation. Independent control for each unit provide convenient and comfort to each room without affecting others.

4.1. WATER-COOLED SPLIT DUCTED (FWSN/ FWSD)

An indoor section and matching outdoor section are connected by refrigerant tubing (hence the name “split”).

The indoor section consists of a fan, indoor cooling coil, and filter while the outdoor section houses the compressor and condenser.

RANGE

| Indoor Unit | FWSN010 ~ FWSN050 |

| Outdoor Unit | FWSD010 ~ FWSD050 |

| Total Cooling Capacity | 3 kW ~ 14 kW 1 Hp ~ 5 Hp |

| Refrigerant | R410A |

| Power Supply | 380 ~ 415V / 3Ph / 50Hz |

4.2. WATER-COOLED PACKAGED (FWLP)

Compact and rigid single unit construction provides convenient installation with no additional piping work as both indoor and outdoor sides are pre-connected.

RANGE

| Model | FWLP010 ~ FWLP100 |

| Total Cooling Capacity | 3 kW ~ 30 kW 1 Hp ~ 10 Hp |

| Refrigerant | R410A |

| Power Supply | 380 ~ 415V / 3Ph / 50Hz |